Main uses

It is suitable for the drying of powdery, granular and fibrous materials in chemical, pharmaceutical, food and other industries, such as the concentration, mixing, drying, and low temperature drying materials (such as biochemical products). It is more suitable for the drying of easily oxidizing, volatile, thermosensitive and toxic materials and materials that are not allowed to be crystal.

Characteristic

The double cone rotary vacuum dryer is a new type of dryer which combines drying and drying. A vacuum drying device is composed of a condenser, a vacuum pump and a dryer. When the container is constantly rotating, the heating surface of the material can be renewed; the indirect heating will not be polluted; the thermal efficiency is high, which is more than 2 times higher than that of the ordinary oven. (if the solvent is not recovered and the condenser can be used), the machine has advanced design, simple internal structure, easy cleaning, and all materials can be discharged completely, and the operation is simple. It can reduce the labor intensity and improve the working environment. At the same time, the material is rotated when the container itself is rotated, but the material is not deposited on the wall, so the heat transfer coefficient is high and the drying rate is large. It not only saves energy, but also makes the material dry and full, and the quality is good. It can be widely used in drying of pharmaceutical, chemical, food, dyestuff and other industries, and is in line with the requirements of the drug management standard "GMP".

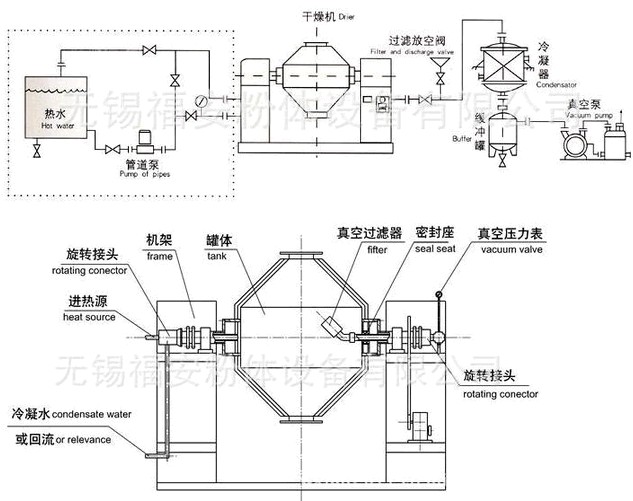

Working principle

The SZG double cone rotary vacuum dryer is a double conical rotary tank. Under the vacuum state of the tank, hot water is heated in the jacket, and the heat is contacted with the wet material through the inner wall of the tank. After evaporation, the moisture of the wet material is evacuated through the vacuum exhaust pipe through the vacuum pump. Because the tank is in a vacuum state, and the rotation of the tank causes the material to go up and down continuously, and the inside and outside turn over, so the drying speed of the material is accelerated, the drying efficiency is improved, and the purpose of uniform drying is achieved.

Main technical parameters

The motor can be equipped with a speed regulating motor according to user requirements, with a speed of 3-13rpm

|

Specifications |

SZG-100 |

SZG-350 |

SZG-500 |

SZG-750 |

SZG-1000 |

SZG-1500 |

SZG-2000 |

SZG-3500 |

SZG-4500 |

SZG-5000 |

|

Tank volume (L) |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Loading volume (L) |

≤50 |

≤175 |

≤250 |

≤375 |

≤500 |

≤750 |

≤1000 |

≤1750 |

≤2250 |

≤2500 |

|

speed (rpm) |

6 |

3 |

||||||||

|

电机功率(kw) |

0.75 |

1.1 |

1.5 |

2 |

3 |

3 |

4 |

5.5 |

7.5 |

11 |

|

Long occupied area ×宽(mm) |

2160× |

2260× |

2350× |

2560× |

2860× |

3060× |

3260× |

3760× |

3960× |

4400× |

|

Gyration height (mm) |

1750 |

2100 |

2250 |

2490 |

2800 |

2940 |

2990 |

3490 |

4100 |

4200 |

|

Design pressure in tank (MPa) |

-0.1~0.15 |

|||||||||

|

Design pressure of jacket (MPa) |

≤0.3 |

|||||||||

|

working temperature (℃) |

Inside of the tank ≤85℃,夹套≤140℃ |

|||||||||

|

When the condenser is used, the type and power of the vacuum pump |

2X-15A 2KW |

2X-15A 2KW |

2X-30A 3KW |

2X-30A 3KW |

2X-70A 5.5KW |

JZJX300-8 7KW |

JZJX300-4 9.5KW |

JZJX600-8 11KW |

JZJX600-4 20.5KW |

JZJX300-4 22KW |

|

When the condenser is not used, the type and power of the vacuum pump |

SK-0.4 1.5KW |

SK-0.4 1.5KW |

SK-0.8 2.2KW |

SK-2.7B 4KW |

SK-2.7B 4KW |

SK-3 5.5KW |

SK-6 11KW |

SK-6 11KW |

SK-9 15KW |

SK-10 18.5KW |

|

weight (kg) |

800 |

1100 |

1200 |

1500 |

2800 |

3300 |

3600 |

6400 |

7500 |

8600 |