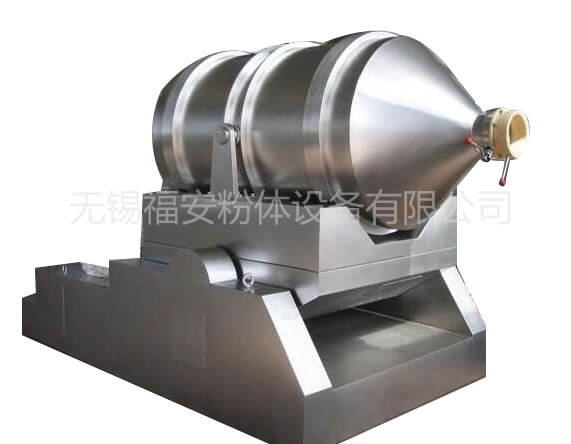

Two dimensional mixer, full name two dimensional motion mixer, as the name suggests, refers to the rotary drum can simultaneously carry out two directions of the movement of the mixer. The two motion directions are the rotation of the rotary cylinder and the swing of the rotary cylinder with the swing frame. The mixed materials are mixed with the revolving barrel at the same time, while the mixing movement occurs at the same time with the swinging of the cylinder. The material is fully mixed in a short time under the joint action of the two movements.

Working principle

Two dimensional mixer consists of three parts: rotary drum, swing frame and rack. The rotary barrel is mounted on a swing frame, supported by four rollers and is axially positioned by two gear wheels. In the four supporting rollers, two of the driving wheels are dragged by the rotating power system to produce the rotating cylinder. The swing frame is driven by a set of crank swing mechanism, the crank swing rod mechanism is mounted on the frame, the swing frame is supported on the frame by the bearing assembly, so that the cylinder is swinging while turning, so that the material in the cylinder is fully mixed.

Characteristics of two dimensional mixer

1. Two rotation uses cycloidal pinwheel reducer or worm gear reducer. Compared with the traditional mixer, it does not accumulate at the bottom, pollution-free and rinse conveniently, which really meets the requirements of GMP.

2. Under the dual function of the rotating mechanism and the swing mechanism, the material of the material is rotated and swinging, so that the material in the cylinder can be fully mixed.

3. The equipment can be equipped with automatic vacuum feeder and interface to facilitate feeding and shorten operation time. High efficiency, low cost

4. Two dimensional motion mixer: simple structure, low failure rate, stable operation, safe operation, no noise, easy to clean, in line with GMP requirements.

5. The volume is much smaller than the normal standard, with less space and powerful function.

Application of two dimensional mixer

It is widely used in mixing of powder and granular materials. It has the characteristics of quick mixing, large mixing volume and convenient discharge.

Technical parameters of two dimensional mixer

Model

Name |

Shape size

L×W×H mm |

Barrel

Capacity L |

Barrel

weight kg |

Loading

volume L |

Maximum loading capacity

kg/p |

Shake / swing

Motion times r/min

|

电机

总功率

kw |

Total weight

kg |

| EYH-10 |

310×400×450 |

10 |

4 |

5 |

2.5 |

85 |

0.021 |

15 |

| EYH-30 |

540×580×900 |

30 |

8.5 |

15 |

7.5 |

61 |

0.19 |

60 |

| EYH-60 |

700×730×1100 |

60 |

15 |

30 |

15 |

50 |

0.4 |

115 |

| EYH-150 |

800×1050×1450 |

150 |

50 |

75 |

37.5 |

37 |

1.15 |

190 |

| EYH-300 |

900×1350×1550 |

300 |

60 |

150 |

75 |

30 |

1.15 |

340 |

| EYH-600 |

1170×1640×2050 |

600 |

140 |

300 |

150 |

23.6 |

3 |

1150 |

| EYH-800 |

1320×1950×2150 |

800 |

200 |

400 |

200 |

19.8 |

3 |

1600 |

| EYH-1000 |

1360×2040×2300 |

1000 |

240 |

500 |

250 |

19.8 |

3 |

1700 |

| EYH-1500 |

1580×2400×2550 |

1500 |

320 |

750 |

375 |

16.2 |

4.4 |

2000 |

| EYH-2000 |

1740×2600×2770 |

2000 |

430 |

1000 |

500 |

16.2 |

7.4 |

2600 |

| EYH-3000 |

1800×2900×2950 |

3000 |

620 |

1500 |

750 |

13.8 |

11 |

3500 |

| EYH-4000 |

1970×3300×3300 |

4000 |

700 |

2000 |

1000 |

12.8 |

13 |

4100 |

| EYH-6000 |

2300×2900×3800 |

6000 |

1100 |

3000 |

1500 |

11.2 |

18.5 |

6100 |

| EYH-8000 |

2540×4100×4050 |

8000 |

1450 |

4000 |

2000 |

10.4 |

22 |

7900 |

| EYH-10000 |

2900×4500×4400 |

10000 |

1650 |

5000 |

2500 |

9 |

30 |

9500 |

| EYH-非 |

可根据用户的要求,现场设计、制造 |

|

|

|

|

|

|

|