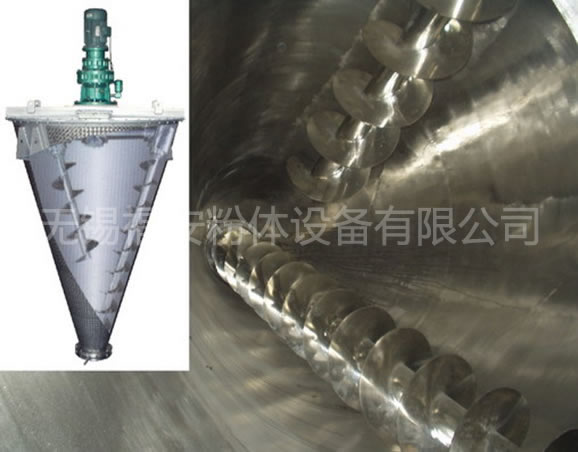

DZH helical ribbon mixer consists of single stage reducer (infinitely variable speed), transmission part, cylinder cover, cylinder, inner screw and outer spiral belt. The discharge valve and other components are made up. The equipment is equipped with a variety of styles (scraper, inner spiral, outer spiral belt), and can also be double cone structure to adapt to different materials and more suitable for mixing of fluid materials with high viscosity. DZH ribbon mixer, it is agitated viscous fluid or thick, wet, paste based, can also be mixed powder. Particle logistics, the machine is widely used in adhesives, silicone rubber, dyes, pigments, ink, paraffin, paint, resin, cream, ointment, detergent, washing powder, food additives, milk powder, salt, monosodium glutamate, chocolate, feed, bio fertilizer, new building materials and so on.

1.The spiral revolution along the wall makes the material move round the cone wall.

2.Spiral self rotation causes the material to rise from the bottom of the cone to the spiral

3.The spiral common and self rotation compound movement makes a part of the material absorbed into the spiral cylindrical surface and is simultaneously subjected to the centrifugal force of spiral rotation, so that a part of the material in the spiral cylindrical surface is discharged to the cone radial.

4.The rising material is reduced by its own gravity

5.The four movements produce convection, shear and diffusion in the mixer, so as to achieve the goal of rapid and homogeneous mixing.

| Model |

Total volume m3 |

Output (t/h) |

Rotation speed (r/min) |

Rotation speed (r/min) |

Motor power (kw) |

Mixing time (min) |

Outer size (L×W×H) |

| 200 | 0.2 | 0.2-0.8 | 143 | 2 | 3 | 6~10 | 890×1620 |

| 300 | 0.3 | 0.3-1 | 143 | 2 | 3 | 6~10 | 940×1670 |

| 500 | 0.5 | 0.5-1.5 | 143 | 2 | 3.5 | 6~15 | 1142×2000 |

| 1000 | 1 | 2-2.5 | 57 | 2 | 5.2 | 8~18 | 1610×2520 |

| 1500 | 1.5 | 2-4 | 57 | 2 | 5.2 | 8~20 | 1636×2800 |

| 2000 | 2 | 2.5-5 | 57 | 2 | 7 | 10~25 | 1970×3130 |

| 3000 | 3 | 4-7.5 | 57 | 2 | 8.7 | 10~25 | 2210×3470 |

| 6000 | 6 | 7-15 | 53 | 1.6 | 18 | 10~27 | 3050×5920 |

| 10000 | 10 | 12-20 | 53 | 1.3 | 29.5 | 10~30 | 3050×5920 |