It is suitable for mixing, dispersing and dissolving liquid and liquid solid materials in coatings, dyestuffs, pigments, ink, paper making, adhesives and other chemical industries.

Characteristics: mixing and mixing are very effective when mixing and dispersing. Mixing and dispersing at high speed can quickly dissolve the material and reduce the particle size.

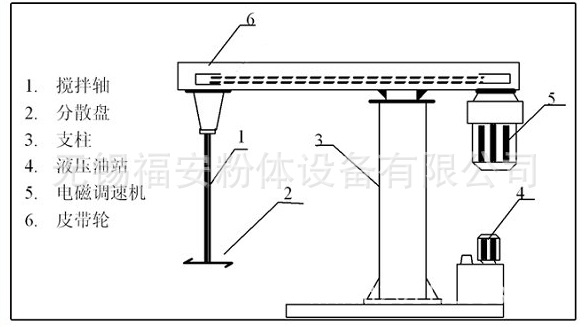

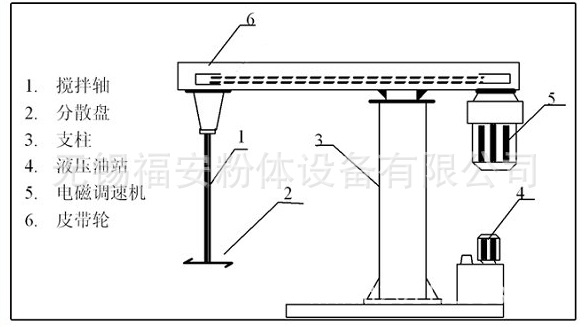

The disperser is also called a mixer. According to the different forms of lifting, they can be divided into hydraulic lifting and dispersing machines and mechanical lifting and dispersing machines. The speed of dispersing machines can be adjusted arbitrarily. It is mainly composed of five parts: hydraulic system, main drive, mixing system, guiding mechanism and electric control box. Each part of the structure is compact and reasonable. Widely used in coatings, solids for mixing, dissolution and efficient equipment and coatings, inks, pigments, adhesives and other chemical products. The common types are emulsifying dispersing machine, explosion-proof dispersing machine, lifting and dispersing machine, stirring dispersing machine, paint dispersing machine, etc.

Main features

Using all kinds of specifications such as electromagnetic speed regulation, frequency conversion speed regulation and three speed and so on, it is stable and powerful, suitable for various kinds of viscosity; hydraulic and mechanical two kinds of lifting and lifting form, rise and fall and rotate freely, adapt to various positions; common and explosion-proof configuration, safe and reliable, simple operation and maintenance, strong production continuity, fast dispersing and dissolving of materials. It has good dispersing effect, high production efficiency, smooth operation and easy installation. There are different power and types for viscosity and treatment capacity of different materials.

Work characteristics

1 The strong centrifugal force is in the radial clearance, the narrow gap between the rotor, and the centrifugal extrusion, the friction of the liquid layer, the hydraulic impact and so on. The material is initially dispersed.

2 The high-speed rotating rotor of the disperser produces at least 15m/s line speed, and the material is fully dispersed and broken under the effect of strong hydraulic shear, liquid layer friction, tearing collision and so on. At the same time, the material is ejected at high speed through the stator slot.

3 The materials of the dispersing machine are constantly ejected from the radial speed, and the flow of the material itself and the wall of the vessel is changed. At the same time, the upper and lower axial suction forces produced by the rotor zone form two strong turbulent flows in the upper and lower parts. After several cycles, the material will eventually complete the dispersion process.

Main points of selection

1. First of all, it is necessary to make clear the effectiveness and purpose of using equipment.

2. In addition, we should understand the nature of the material in detail.

3. According to the material, the agitator type of the dispersing machine is selected again.

4. Thirdly, the operation parameters and structure design of the disperser should be determined.

5. When considering the cost of dispersing equipment, installation cost should also be considered.

Adaptability

Dielectric properties

1 Different types of dispersing machines are selected in gaseous, liquid or mixed states. ZQDF is used in air, ZQDF - Y is used for liquid, ZQDF - 2 (or -3) is used for steam, otherwise it is easy to cause misoperation. ZDF series multi-function dispersing machine can be used in gas. Liquid. It is best to specify the state of the media when the time is set.

2 Medium temperature products of different specifications, otherwise the coil will burn, seals aging, and seriously affect the service life.

3 The viscosity of the medium is usually below 50cSt. If the value exceeds this value, the diameter is greater than 15mm, and the ZDF series multifunctional dispersing machine is used for special orders. The diameter is less than 15mm and the high viscosity dispersing machine is set.

4 When the medium cleanliness is not high, the recoil filter valve should be installed in front of the disperser. Low pressure fashion can be used as a direct acting diaphragm disperser, for example, CD - P.

5 If the medium is directional and does not allow reverse flow ZDF - N and ZQDF - N only need two-way flow, please make special request.

6 The medium temperature should be selected within the allowable range of the disperser.

Pipe parameters

1 Select valve port and type according to medium flow direction and pipe connection mode. For example, for a pipeline to switch to two pipelines, small path selected CA5 and Z3F, medium or large diameter please select ZDF - Z1/2. If you want to control the convergence of two pipes, please select ZDF Z2/1.

2 The nominal diameter is selected according to the flow and valve Kv values, and the inner diameter of the pipe can also be selected. Please note that some manufacturers do not have the Kv value, often the size of the valve port is smaller than the diameter of the interface, so we must not covet the low price and make a mistake.

3 The minimum working pressure difference of the working pressure difference above 0.04Mpa is an indirect pilot type, and the direct or stepwise direct type must be selected for the minimum working pressure difference near or less than zero.

Environment condition

1 The maximum and minimum temperature of the environment should be selected within the allowable range. If there is excess deviation, special orders should be put forward.

2 In case of high relative humidity and dripping rain, we should choose waterproof dispersing machine.

3 Special varieties, such as marine dispersing machines, should be selected for occasions such as vibration, bump and impact.

4 In corrosive or explosive environments, corrosion resistance should be preferred according to safety requirements.

5 If the environment space is restricted, please use multi-function dispersing machine, because it eliminates bypass and three manual valves and is convenient for online maintenance.

Power supply condition

1 According to the types of power supply, AC and DC dispersing machines are selected respectively. Generally speaking, it is convenient to use the AC power supply.

2 AC380V, AC220V and DC24V should be preferred as far as voltage specifications are concerned.

3 Power supply voltage fluctuation usually AC selects +%10%, -15%, DC tolerance of about%10, if overrun, must adopt voltage stabilizing measures or special order requirements.

4 Rated current and power consumption should be selected according to the power supply capacity. It should be noted that the VA value is higher when AC starts. When the capacity is insufficient, the indirect guided dispersing machine should be preferred.

Installation and debugging

Install

It is usually installed on the basis of the expansion bolt on the basis of the level. There are cables between the electric cabinet and the explosion-proof operation box. (the cable is usually connected by the unit electrician, and the supplier provides the cable specifications).

Debugging

(1)Start the lifting switch to see whether the lifting is flexible and reliable.

(2)Start the mixing switch and rotate speed to medium speed to see if it is stable.

Operating procedures

Before driving

1、Check whether the oil level of the disperser is added to the specified position, and the low oil level should be added to the specified oil level, and high should be put to the specified position.

2、Check the tightness of the triangle belt.

3、The impeller should be flexible and free of friction.

4、Check whether the fasteners are loose and whether there is leakage in each sealing part.

5、Turn on the main motor of the disperser and check whether the rotation of the stirring is the same as that specified by the equipment.

6、It is confirmed that the above inspection work can be carried out without error.

Drive a car

1、The impeller is placed in the center of the distributor container, pressing the down button to the lowest position or required position.

2、Two handles must be locked before driving.

3、Open the main motor and press the button at the operating speed

4、During the operation, attention should be paid to the current frequently. If overloading operation is found, the reasons should be stopped for inspection, and then the dispersing machine should be continued after taking measures.

Parking

1、First stop the main motor, so that the impeller is stopped.

2、Turn on the rising button of the disperser, so that the impeller of the main shaft rises to the top of the container, and the impeller is cleaned.

Maintenance

1、The triangle belt should be equal in length, put into the transmission box, tighten properly, tighten the bolts of the slide plate, and cover the upper cover.

2、If the equipment does not need to be stopped for a long time, the power supply must be cut off, all the scrubbing is cleaned, the lubricating parts shall be oiled, and the main shaft and the oil cylinder shall be oiled and rust protected.

3、46# hydraulic oil for fuel tank is replaced every half a year and the oil tank is cleaned. The filter net is cleaned once a month and cleaned once in two or three days after changing oil.

4、The gear, bearing, ball, shaft and shaft sleeve and oil cylinder are rotated by the dispersing machine. Once a week, oil is injected. During the use, it is found that overheating or abnormal noise should be checked in time.

5、If the overheat is caused by the thermal relay action, the reset button of the thermal relay must be pressed before the operation can be continued.

6、The AC contactor is checked every six months, and the equipment is used once a year.

7、The disperser regularly checks loose parts such as bearings and oil seals, and finds wear and tear immediately.

8、You must check the dispenser pot once a day, and make a careful record of the pot.

9、When the blade diameter is D, the container diameter is 3 4 to 3. 9 D. the blade height is 0. 5 to 0. 7 d. the charging height is 2 4 to 3 D, which can achieve good dispersion effect.

10、Regular oil is added to the column and mixing shaft.

11、Unscheduled inspection of the transmission triangle

| Specifications |

FS1.5 |

FS4 |

FS11 |

FS22 |

FS37 |

FL45 |

FL90 |

| Motor power (KW) |

1.5 |

4 |

11 |

22 |

37 |

45 |

90 |

| Rotational speed of dispersion shaft (r.p.m) |

0-1450 |

0-1450 |

0-1450 |

0-1450 |

0-1200 |

0-1200 |

0-1000 |

| Dispersing wheel diameter .(mm) |

150 |

200 |

250 |

350 |

400 |

450 |

600 |

| Frame lift stroke (mm) |

600 |

800 |

900 |

1200 |

1200 |

1600 |

1600 |

| Pump power (KW) |

0.55 |

0.55 |

0.55 |

0.75 |

0.75 |

1.1 |

2.2 |

| Volume of material cylinder (L) |

50 |

200 |

400-600 |

600-1000 |

1000-2000 |

1000-2500 |

5000 |

| Weight (Kg) |

120 |

400 |

800 |

1500 |

1700 |

2100 |

2600 |

| Shape size |

A (mm) |

1400 |

1700 |

1750 |

2200 |

2200 |

2600 |

2700 |

| B (mm) |

940 |

1300 |

1800 |

2100 |

2100 |

2700 |

3000 |

| C (mm) |

350 |

600 |

900 |

1100 |

1100 |

1400 |

1600 |

| W(mm) |

350 |

540 |

650 |

900 |

900 |

1000 |

1500 |