.jpg)

Summary

The emulsifying machine cuts, disperses and impacts the material through the high-speed rotation of the homogeneous head connected with the engine. This will make the material more delicate and promote oil and water blending. It is widely used in cosmetics, shower gel, sunscreen, and many other cream products. The sauce, fruit juice, etc. in the food industry. Ointment in the pharmaceutical industry. Petrochemical, paint, paint, ink and so on will be used for emulsifying machines.

Working principle

The rotor and stator are precisely matched, and the working head (rotor and stator forgings) is claw like structure, with two-way suction and high shearing efficiency. The intermittent high shear dispersive emulsion homogenizer is a high speed, high frequency, strong circular cutting speed, angular velocity, and so on. Under the action of stator, a strong, reciprocating hydraulic shear, friction, centrifugal extrusion, and liquid flow collision are formed in the gap between the stator and the stator. Comprehensive effect, materials in containers in the above working process, and ultimately get products.

Intermittent high shear working process :

1.Under the centrifugal force generated by a high-speed rotating rotor, the material in the diagram is sucked into the working chamber from the upper and lower feed areas at the same time.

2.

Strong centrifugal force moves the material from the radial to the narrow and precise clearance between the rotor and the rotor. At the same time, it is subjected to centrifugal extrusion, impact and other forces, so that the material is initially dispersed and emulsified.

3.At the outer end of the rotor at high speed, the speed of at least 15m/s is generated at least, the maximum can be reached to 40m/s, and the strong mechanical and hydraulic shear, the liquid layer friction and the impact tearing are formed, so that the material is fully dispersed, emulsified, homogenized and broken, and is ejected through the stator slot at the same time. The emulsifying machine cuts, disperses and impacts the material through the high-speed rotation of the homogeneous head connected with the engine. This will make the material more delicate and promote oil and water blending. The sauce, fruit juice, etc. in the food industry. Ointment in the pharmaceutical industry. Petroleum chemical industry, paint, paint, ink and so on will use emulsification machine. The application of mixing, stirring, dispersing, homogenizing, emulsifying and grinding in the process of experiment or industrial production.

4.As the material itself and the wall of the container change the direction of the material at high speed, the flow is changed under the resistance of the material itself and the wall of the container. At the same time, the upper and lower axial suction forces of the rotor zone form the two strong flip flow of the upper and lower parts. After several cycles, the material will eventually be dispersed, emulsified and homogenized.

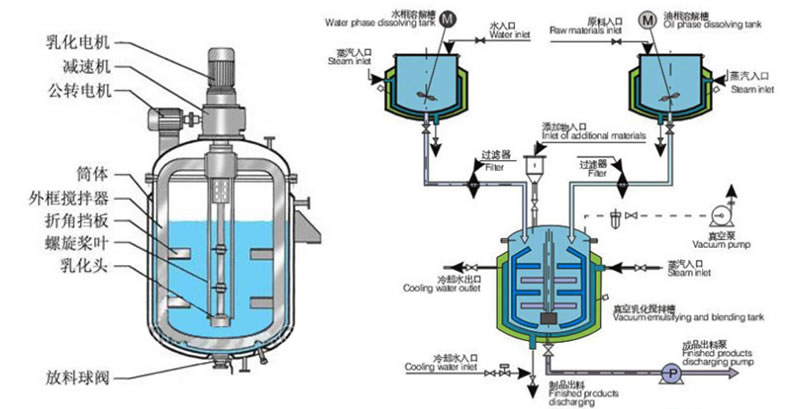

Internal structure and process flow chart :

Machine characteristics of emulsifier

Stable operation, low noise, easy cleaning, flexible and continuous use. The material can be superfine dispersed and emulsified. It can be widely applied to emulsification, homogenization and dispersion in industrial production.

Application field of emulsifier

The application field of emulsifier is very wide, such as adhesives, paint and paint, cosmetics, food, medicine, plastic resin, printing and dyeing, ink, asphalt and other industries are widely used.

Fine chemicals: plastic, filler, adhesive, resin, silicone oil, sealant, slurry, surfactant, carbon black, defoaming agent, brightener, leather assistant, coagulant and so on.