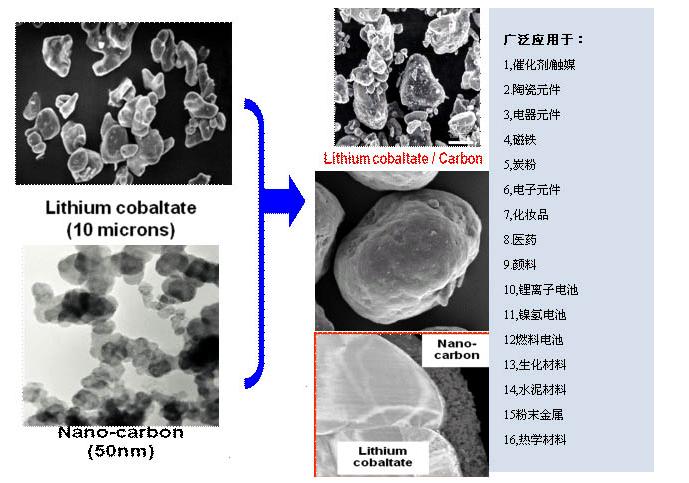

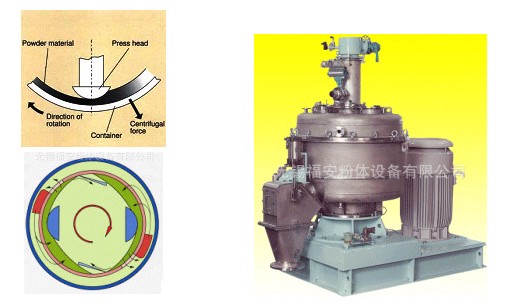

This equipment is mainly aimed at the battery industry equipment, the intake port (negative material, conductive extrusion, adhesive, electrolyte) through mechanical fusion and high precision mixed treatment, composition of the distribution of different material components, improve the utilization of the product material, composition of the components of different materials of the composite, reduce the BET ratio of the product The area of the product is filled with high density. The nano powder is coated on the micron sized particles to improve the physical and chemical properties of the powder. Mechanical fusion equipment is developed based on this principle. The material is rotated at high speed in the rotor. It is tightly attached to the wall under centrifugal force and passes through the rotor and stator extrusion head at high speed. At this moment, the material is subjected to the action of squeezing pressure and shear force at the same time. Because of high speed rotation, the material is repeated around the rotor and stator, and it is constantly subjected to the action of squeezing pressure and shear force. Under the action of friction, the particle surface reaches a kind of mechanical melting state, and the nanometer sized ultrafine powder is coated in micro. On the grain of the rice grade.

Mechanical fusion machine and shock machine are suitable for super fine ceramic powder. Through this mechanical fusion, super fine ceramic powder is inlaid on the surface of metal powder, thus producing a kind of metal electromagnetic properties, but also like ceramic insulation material.

| Model | Power (kw) | Speed (rpm) | Loading volume (L) |

| ZJ-6 | 4 | 0-2000 | 2 |

| ZJ-300 | 30 | 0-1500 | 15~20 |

| ZJ-600 | 75 | 0-1100 | 30~35 |

| ZJ-1000 | 132 | 0-750 | 100~120 |