Summary :

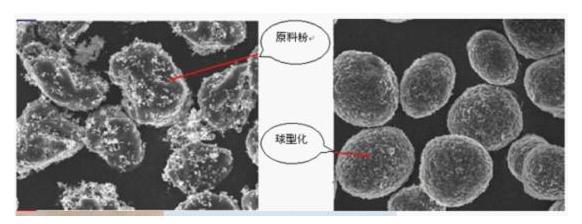

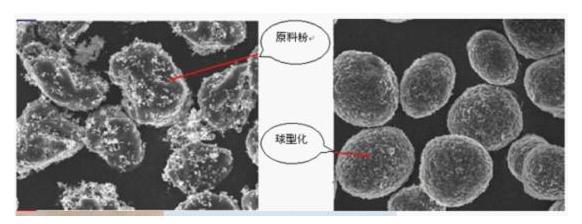

VH high temperature coating machine is a hybrid equipment developed by the advanced technology of foreign countries to improve the mixing efficiency, to make the particles fully mixed and dispersed, and to achieve a micrometer mixing and uniform mixing machine. It has a wide range of uses, such as mixing, spheroidal, dispersing, crushing, drying, granulation and coating functions of slurry, liquid and powder.

Principle :

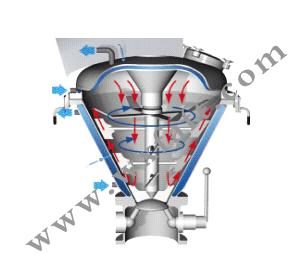

The VH mixer has a conical mixing chamber with a central shaft and its rotation speed can reach 30 m / s. The centrifugal force is generated by the speed of the rotating shaft to push the product into the inner wall of the mixing chamber. At this time, the conical shape of the cavity and the shape of the blade cause the product to move upward along the inner wall. The product is then guided by the specially designed mixer cover to the center of the mixer, and then retreated to the bottom of the mixing chamber to start a new round of mixing process.

Reheating :

In graphite powder, add asphalt and other additives, can be heated, usually heated to 0-1000 degrees, the equipment side mixed edge heating, play the role of mixing + heating + heat preservation, temperature controllable, adjustable speed, PLC touch screen operation 。

| Model |

VH-50 |

VH-100 |

VH-200 |

VH-300 |

VH-500 |

VH-1000 |

VH-1500 |

VH-2200 |

| Total volume (L) |

50 |

100 |

200 |

300 |

500 |

1000 |

1500 |

2200 |

| Effective volume (L) |

25-30 |

50-60 |

100-120 |

150-180 |

250-300 |

500-600 |

750-900 |

1200-1500 |

| 功率(KW) |

5.5 |

11 |

22 |

30 |

45 |

55 |

75 |

90 |

Medium type Experimental model