Introduction of equipment

The high speed superfine dispersion mixer is suitable for the process requirements of a large viscosity. The special multi-layer fixed and rotor structure has remarkable superfine dispersion and crushing performance. When the material is imported from the equipment, it is automatically inhaled into the working chamber and through multiple shear surfaces, hundreds of times of intense shear are produced. The combined action of cutting, impact, grinding and cavitation makes the material fully dispersed, broken and refined. Compared with the traditional dispersing equipment, it has the advantages of simple structure, quick completion of dispersing and refining, remarkable effect, low energy consumption and easy maintenance.

high speed ultrafine dispersing mixer is a kind of ultra-fine powder raw material which is specially designed for the electronic and lithium battery slurry in production, and it is difficult to effectively carry out the ultrafine dispersion. After the ultrafine dispersing machine, the electronic and lithium battery slurry fully scatters the fine powder reunion of the reunion. Dispersion and depolymerization, and materials can be quickly and efficiently dispersed through the working chamber, with little heat and no dead angle. The equipment is optimized for the special properties of high sticky materials. After the material is dispersed, the material is transported to the outside of the pump through the special dump plate. The material is not leaked without material. No medium is needed to cool the seal, so it will not cause the pollution of the external medium to the material.

The machine is made of sanitary stainless steel and made by Seiko. On the basis of ensuring the mixing effect of the powder, the stability of the equipment is ensured to the maximum extent.

Equipment features

⑴The equipment is compared to the traditional equipment :

☆ High efficiency and energy saving

The traditional equipment needs 8 hours of scattered processing, the equipment is completed in about 1 hours, the effect of ultrafine dispersion is remarkable, and the energy consumption is greatly reduced.

☆High speed and high quality

The stirring speed of the traditional equipment is tens of minutes per minute and the speed of the dispersing function is within 1500 turns per minute. It only completes the macro dispersive processing, the superfine dispersing ability is very limited; the rotational speed of the equipment is 5000~6000 revolutions per minute, the shear force produced by the super high line speed, and the powder in the instant ultrafine dispersed slurry. 。

⑵The equipment is compared to the same equipment :

☆No pollution, no leakage

The same kind of equipment are both built-in and external contact seal, the built-in type of solvent corrosion resistance is poor, the particles are easy to enter the friction surface, the wear is fast, the slurry is easy to leak, the external type needs the medium cooling, the medium is easy to enter the slurry and lead to pollution.

For the particularity of electronic and lithium battery electrode sizes, the equipment has designed a non-contact seal combination, combined with the internal negative pressure structure, without any cooling medium, and can ensure no pollution and leakage.

☆Improvement of fever problem

In the processing of the same kind of equipment, after the high viscosity material enters the cavity, the transportation performance is poor because of the large back pressure, which causes the material to stay in the equipment cavity for a long time and seriously heat.

On the basis of ensuring the effect, the equipment reduces the back pressure resistance, and enhances the transport capacity, so that the retention time of the material is greatly shortened, and the heating status of the high viscosity material is reduced.

☆Multilayer and multidirectional shear dispersion

The structure of the fixed rotor and other components of the same kind of equipment is single, and the multi layer and multi-layer structure is simple and repeatable. The same cogging structure is easy to pass through the short circuiting of the working cavity without dispersing the biological material.

The structure of the stator and rotor of the equipment adopts the concept of multi-layer and multi-directional shearing. The assembly structure makes the material be cut and dispersed in different directions, and the short-circuit phenomenon is eliminated, and the ultrafine dispersion is more thorough.

Process application

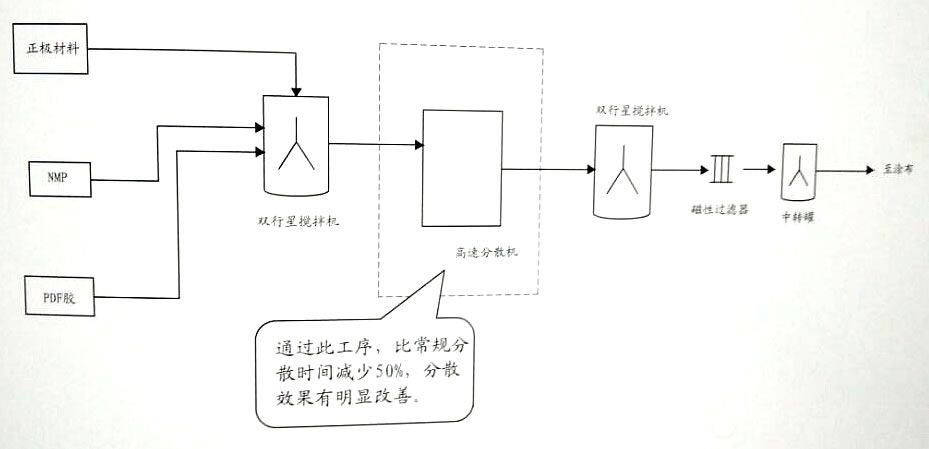

☆ Ultrafine dispersion of positive and negative size of lithium battery

☆ Ultrafine dispersion of powder liquid in base material of PCB

☆ Ultrafine mixed dispersion of high viscosity material powder

☆Ultrafine disaggregation and dispersion of nanomaterial aggregate

Application scope

Electronic batteries: lithium battery cathode slurry, lithium battery negative paste, printed circuit board base slurry.

Nanomaterials: ultrafine calcium carbonate, silica and other nanomaterials depolymerization, solid-liquid dispersion of Nanopowders

Fine chemicals: hot-melt adhesives, sealants, glue, flocculants and surfactants.

Biopharmaceutical: ointment, ointment, cream, injection, microcapsule emulsion, filler dispersing

Equipment parameters

The series is divided into two models: single stage horizontal (FA- WS), multi-stage horizontal (FA-WM), single stage vertical (FA-LS), multi-stage vertical (FA-LM).

| Serial number |

Model |

Power (Kw) |

Speed (RPM) |

Size treatment (Kg/h) |

| Electronics |

Lithium battery |

| Single level |

1 |

FA- WS(LS) 5 |

5.5 |

3000-6000 |

20 ~ 300 |

2 ~ 20 |

| 2 |

FA- WS(LS) 11 |

11 |

3000-6000 |

50 ~ 1000 |

20 ~ 100 |

| 3 |

FA- WS(LS) 15 |

15 |

3000-6000 |

500 ~ 2000 |

50 ~ 200 |

| 4 |

FA- WS(LS) 22 |

22 |

3000-6000 |

1000 ~ 3000 |

100 ~ 300 |

| 5 |

FA- WS(LS) 30 |

30 |

3000-4500 |

2000 ~ 5000 |

200 ~ 500 |

| 6 |

FA- WS(LS) 45 |

45 |

1500-3000 |

3000 ~ 8000 |

300 ~ 1000 |

| Multistage |

1 |

FA- WM(LM) 11 |

11 |

3000-6000 |

50 ~ 750 |

10 ~ 100 |

| 2 |

FA- WM(LM) 15 |

15 |

3000-6000 |

500 ~ 1500 |

50 ~ 200 |

| 3 |

FA- WM(LM) 22 |

22 |

3000-6000 |

750 ~ 2500 |

100 ~ 300 |

| 4 |

FA- WM(LM) 30 |

30 |

3000-4500 |

1500 ~ 3500 |

200 ~ 500 |

| 5 |

FA- WM(LM) 45 |

45 |

1500-3000 |

2000 ~ 5000 |

300 ~ 1000 |

| 6 |

FA- WM(LM) 55 |

55 |

1500-3000 |

3000 ~ 8000 |

500 ~ 1500 |